How To Solder Car Speaker Wire

Keep one probe on the copper and other on either terminals- see if you hear the beep sound or not.

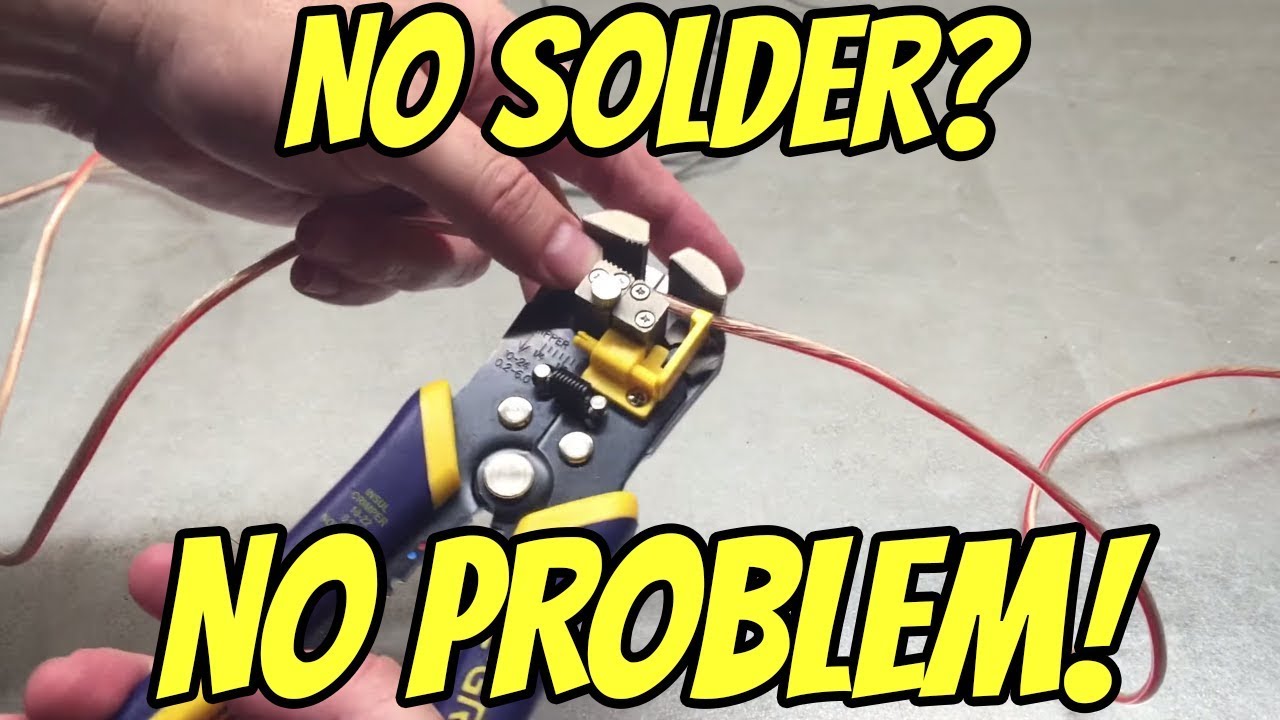

How to solder car speaker wire. Soldering also comes in handy for troubleshooting broken wires or incompatible wire ports. 1If you can wire and solder guitar electronics its definitely within your scope. Its easier to solder correctly than to crimp without proper tools.

Sent from my iPhone using Tapatalk. Both are viable but the clip has the definite edge. If you dont then it might be best to go with the connectors.

Clips are the best way to go and the easiest to maintain. Its especially important when youre working on your cars speakers and the like since easier methods can come undone so quickly. Crimp terminals are often preferable to soldering but here is a trap.

Also solder creates a hard spot along the wire so in portable systems or anyplace that the wires vibrate the wire could fracture at that hard spot. If that is not the case you should cut off the parts that is touching and test again. Audiophiles recommend soldering speaker wires for optimal speaker performance and high sound fidelity.

A clip can be easliy realigned with a pair of needlenose and and cleaned with some steel wool. You melt the solder onto the wires to stick them together and as the solder cools it forms a permanent bond. Next is the quality of the solder joint.

A little solder can go a long way when fixing cables. Allow to cool briefly and repeat for the other wire. Doing so will result in an ineffective joint.