Do Soldering Tips Wear Out

Remember to keep tips always tinned even when you finish your job.

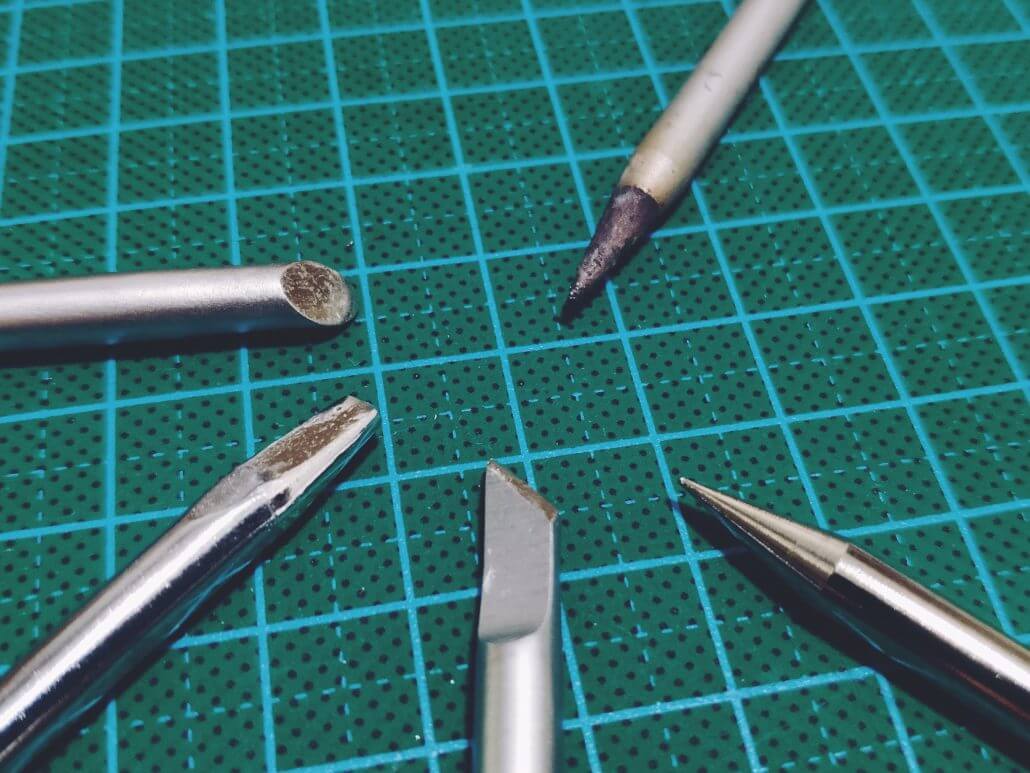

Do soldering tips wear out. NEVER file a soldering tip. To reduce the erosion wipe off the tip between soldering to remove any drops of solder. Its inevitable for soldering tips to wear out over time and need replacing.

Protecting your solder tips can start as early as from the beginning of a solder tips lifetime. For example the sponge leaves your tip clompletely clean and the brass wool leaves a small layer of solder which prevents tip oxidation. Corrosion from acidic or highly aggressive fluxes.

A hollow forming in the end of the tip cleaning and re-tinning has no effect or needs frequent repeating. Soldering tips wear out over time and eventually need replacing but taking steps to care for your tips can extend their life save you money and improve the results of your soldering work. They are copper because when you apply the heat to a solder joint it gets soaked OUT of the tip and the heat sent DOWN the tip from the heater element has to replenish that heat in a timely manner for the next soldering operation.

As any novice handyman would agree improper tip maintenance is. Regards JBC Soldering SL. Once the plating gets even a pin hole in it the molten tin will eat out the copper core of the tip very quickly.

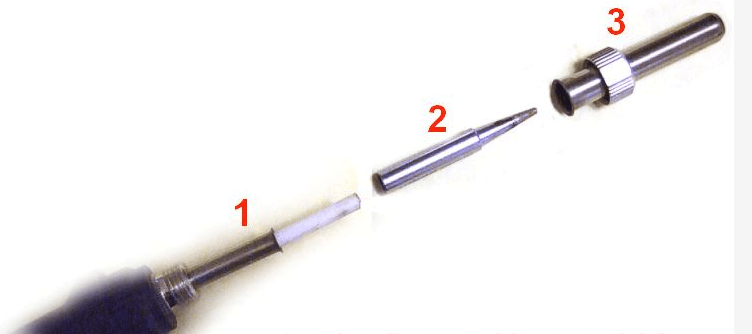

There are various factors that make every soldering iron tip wear out. Experienced operators are also likely to experience wear and tear too. Tip plating failures for all solder tips can be divided into four main classes.

Metcal some of the Hakko brands etc NEVER. In addition to that soldering iron tip tends to wear out as time progresses and will eventually require a replacement. Eventually every tip will wear out and will need replacing when it becomes rough or pitted.