How To Clean A Butane Soldering Iron

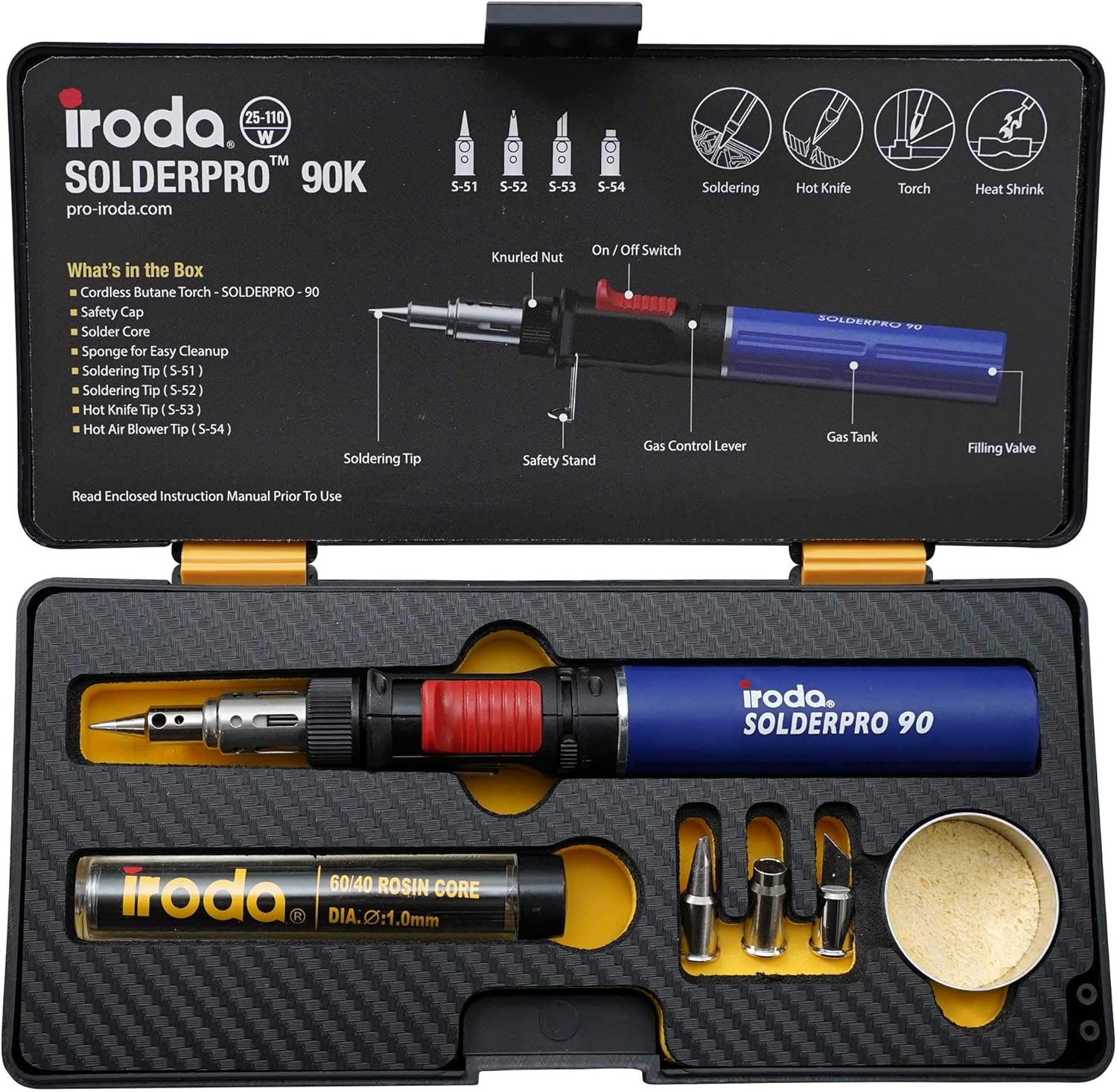

1 x Wireless Butane Torch.

How to clean a butane soldering iron. When soldering you need to heat both sides of the joint and have the two pieces of metal melt the solder. 1 x Protective Cap. The butane solder is very easy to clean and the wet sponge removes excess solder.

How can I clean the catalyst without damaging it. In about 20 seconds it should be hot enough to solder whatever you are working on. Again NEVER EVER get a file anywhere near a non-shitty soldering iron.

You are running the iron much too hot turn it all the way down so the catalyst is only just glowing if thats too cold turn it up slowly. Maybe some bits of material I used to file the irons tip got into the catalyst. You can use the tool either as butane torch for heat shrinking and other applications or you can attach soldering tips to the tool and use it as a soldering iron.

As the soldering tip has to be completely clean before solder to heat up and solder. Ensure that you switch off the soldering iron properly so that you stop the gas flow. I dont want to leave it with a residue that makes if fail altogether but I dont know the chemistryphysics of what might happen with a cleaner.

Heat Up 25 sec. For using the soldering iron for a longer time clean the soldering tip after every use. The Iso-tip butane soldering irons feel like a midway option between the Weller and Dremel in the sense that they are suitable for both smaller jobs like electronics and larger jobs like automotive parts.

To do that there are a few steps to get rid of that butane build up. SOLDERPRO-150 Child Proof. To turn it off bring the lever back to the down position.