How To Improve My Tig Welding

Use clean dry filler rod.

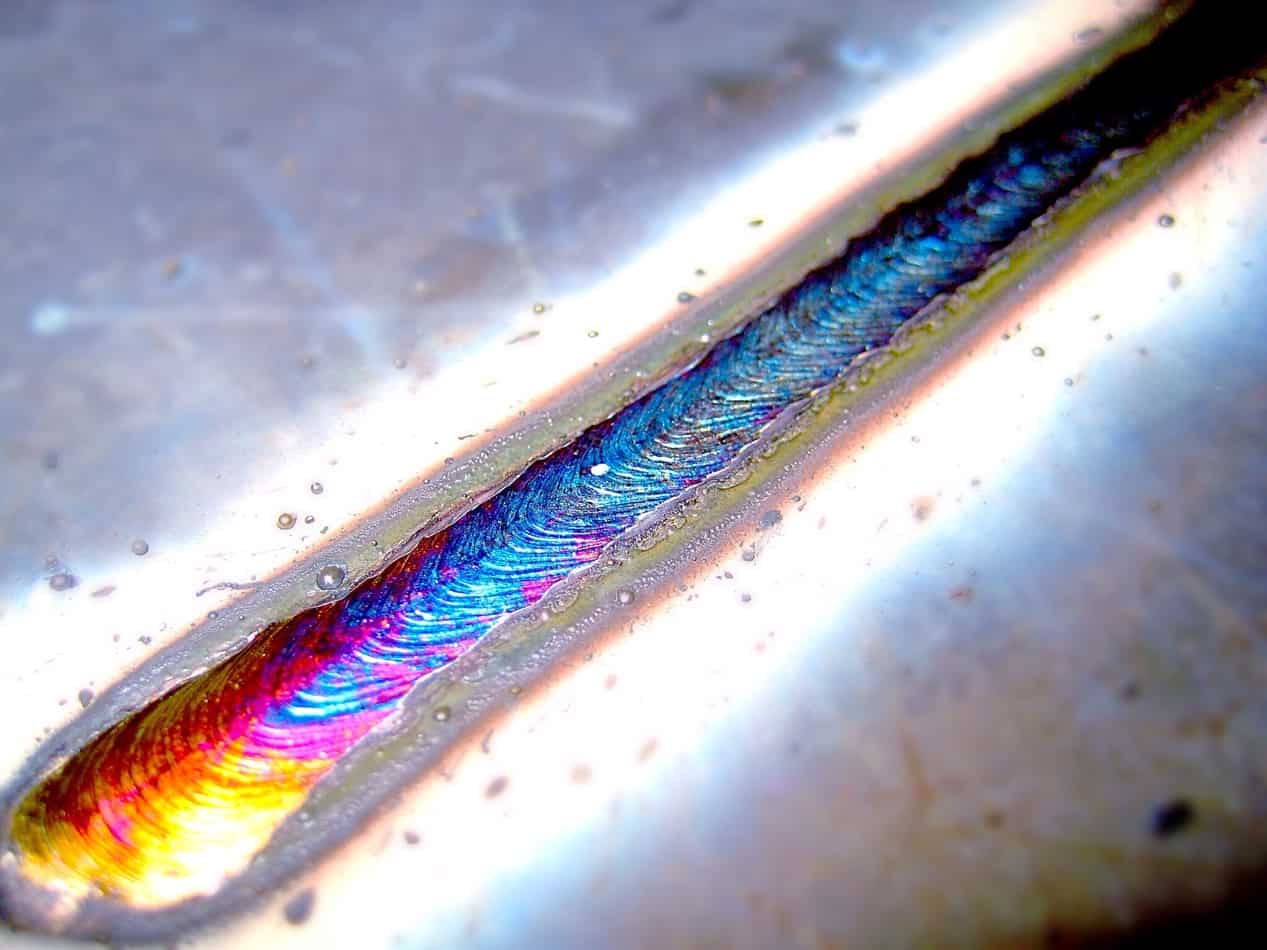

How to improve my tig welding. Cleaning and gas coverage will make it shiny and get rid of that rough look like the left side has. TIG welding must be operated with a constant current power source either DC or AC. It will weld another and easier.

Relatively new to Tig welding any advice on how to improve would be greatly appreciated. Clean the scale off the metal before you weld it. Current is related to the depth of penetration the welding speed and the quality of the weld.

I found using them improves coverage. TIG is suitable for welding in titanium copper among others and it is an incredible application that is suitable for tricky welds. Using an inverter power source is one of the first steps you can take to improve TIG welding efficiency.

After practicing autogenous welds take the next step in TIG welding by adding filler metal. Posted by 5 minutes ago. If it is at all possible use gas lens as they will improve shielding gas coverage as well as offer you better joint accessibility which should greatly improve your TIG welding efficiency.

Tungsten Inert Gas welding is another type of welding that you can try out. Im 14 and just started I keep my auto-darkening helmet to go to around shade 10 in dark-state and I dont know what Im doing wrong to not be able to see the weld puddle that is present during welding. Sharing my go to method for TIG welding up a gap.

Make sure your rod is clean and dry. Tig welding can produce beautiful looking welds and more importantly x-ray quality deposits on some of the most critical welding applications. Hold the rod so it rests horizontally at approximately a 15-degree angle to the workpiece.