How To Prepare Soldering Flux

A great way to do this is to place your materials in a pickle pot and clean them for a couple of minutes.

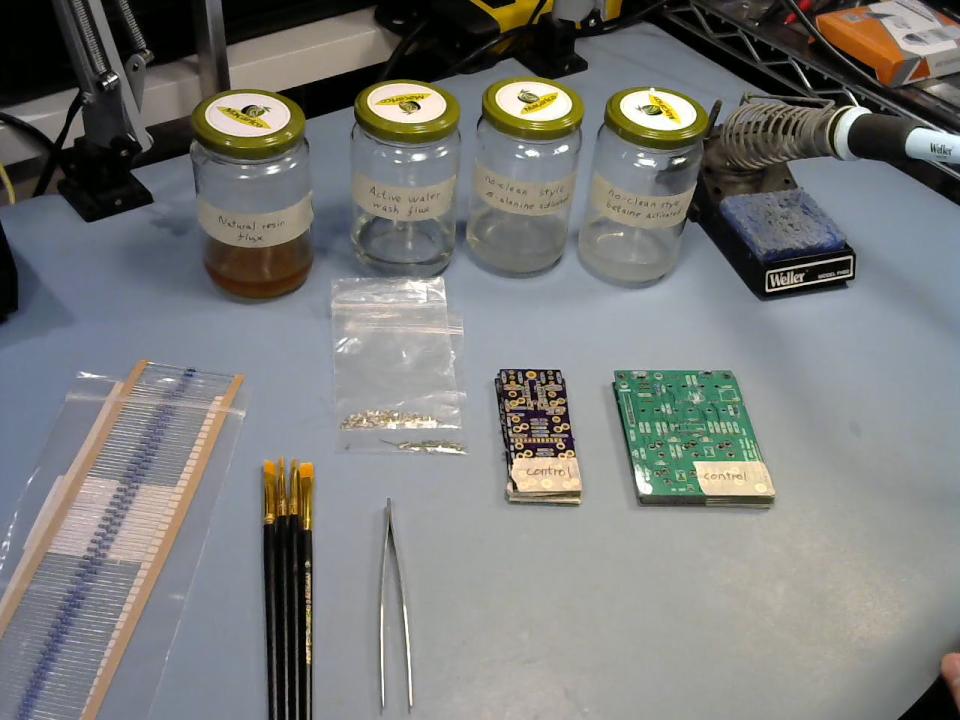

How to prepare soldering flux. Flux is also formulated to remove any oxidation from pipe and actually etches pipe surface in preparation for the soldering process to be successful. The tinplate metal you want to solder may need some preparation before its ready. If there is any debris or dirt it will have to be cleaned off.

Tinning will also help to protect the tip and reduce wear. Clean and Prepare Your Materials. Flux will help to remove any deposited oxides from the surface of the metals thus leading to better joints.

It removes oxidation from the surfaces to be soldered. Once your materials are spick and span use your tongs or a pair of pliers to gently place your metals together on a brick. You can use a flux pen to dispense flux.

The tinning process protects the tip from oxidation reduces wear and enhances heat transfer. Push the soldering gun onto a side of your wires to melt flux. Spread the flux over the area you will be soldering making sure to cover the wires fully.

Do not touch it. A VOC-free water-based flux was chosen for the tinsilvercopper experiment. Got home and realized it doesnt mention rosin anywhere on the package and neither does the online listing.

Do nothing until all of the juice has strained through. Maintain proper angle between the two. Use a small paintbrush or your fingers to scoop up a small amount of soldering flux.