How To Properly Solder Small Wires

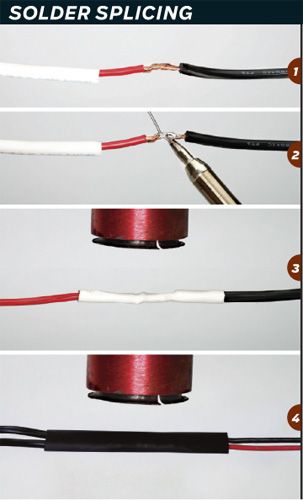

Using a Wire Stripper Strip the Wires to Desired Length.

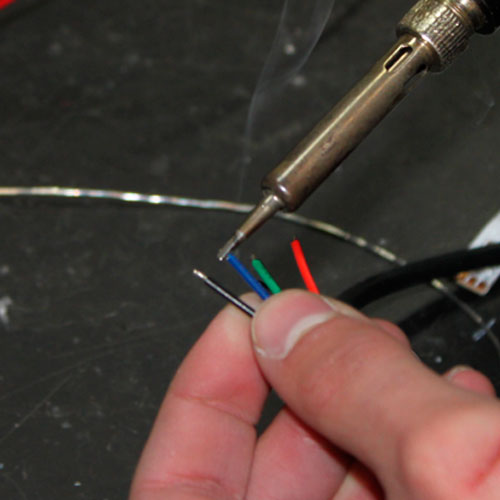

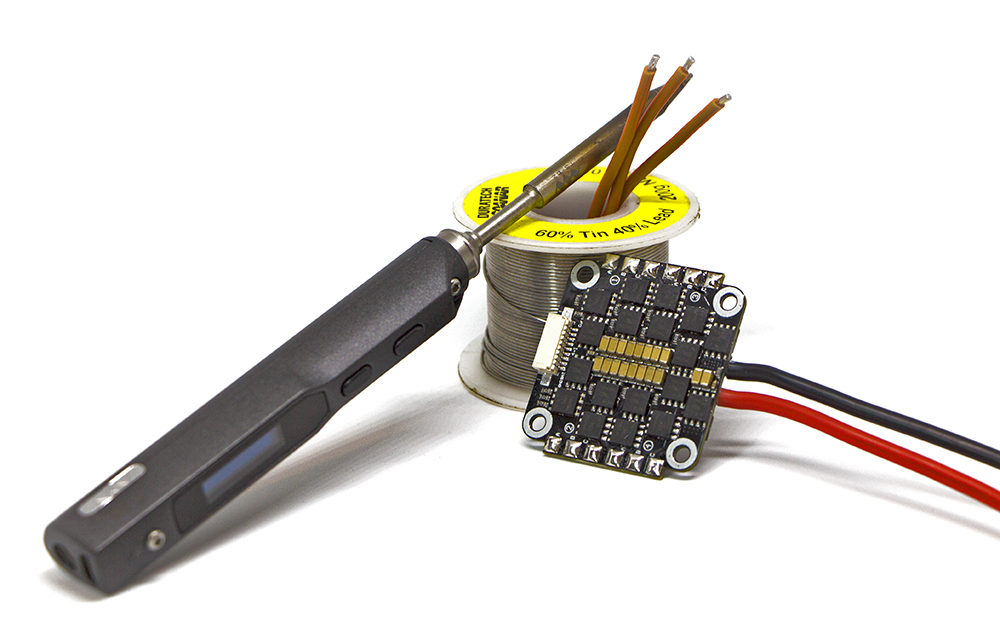

How to properly solder small wires. Instead allow the iron to heat the wire to the point that it melts the solder. Then touch the tip of the soldering iron to the bottom side of the wire so the solder pool is in contact with the wire. How to Solder Wires Together Correctly Like a Pro.

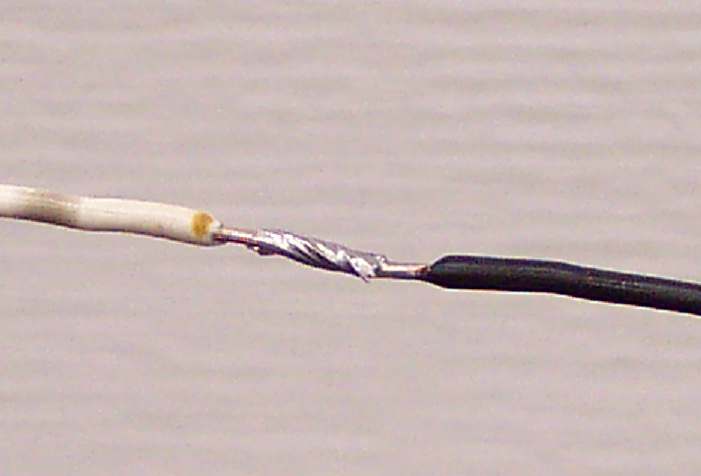

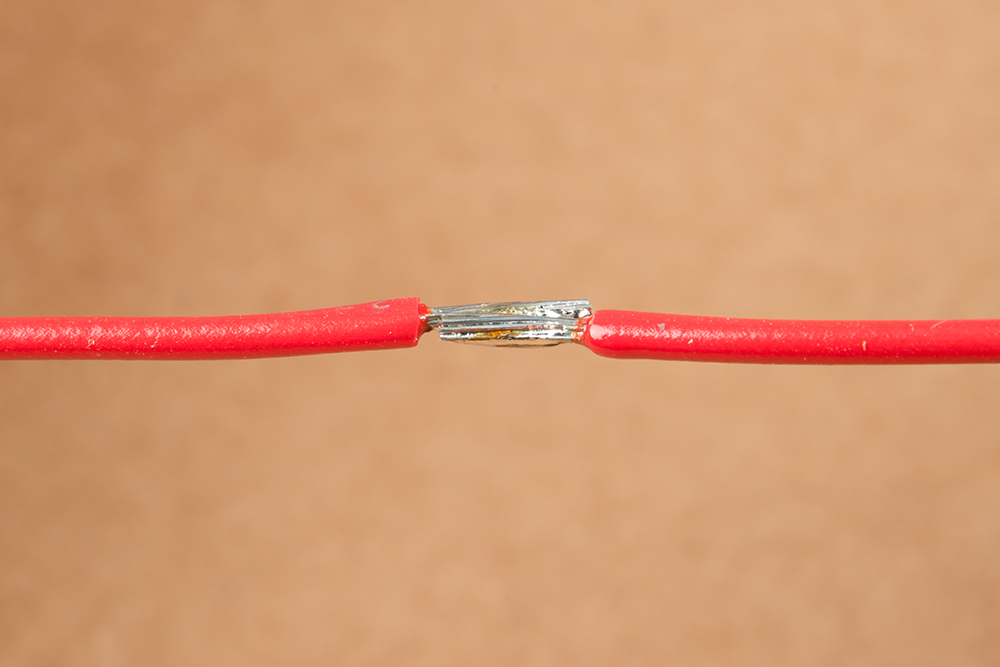

How to Solder Wires. If you do it right you get a big melted bead ON the iron but with the wires running through the middle of it. Remove the soldering iron and wait a few seconds to let the soldered connection cool and harden.

Add solder to the connection. This will help conduct heat to the wire. If you did the cable and the tag at the same time by the time the solder properly melted the wire insulation would have started to.

You need to apply the heat to the metal part on the plug because that takes the longest to heat and melt the solder. When you solder items together youll typically be using the hot metal tip of the iron to melt a small amount of solder alloy around and between the components or surfaces being joined. Once the connection evenly turns the correct silver color of solder remove the soldering iron and allow the joint to cool.

Heat both the wire and the terminal simultaneously. When melting the solder to the wires try not to touch the iron with the solder. You have to use leaded solder though because this will pull the enamel wire right onto the center of the pin or pad.

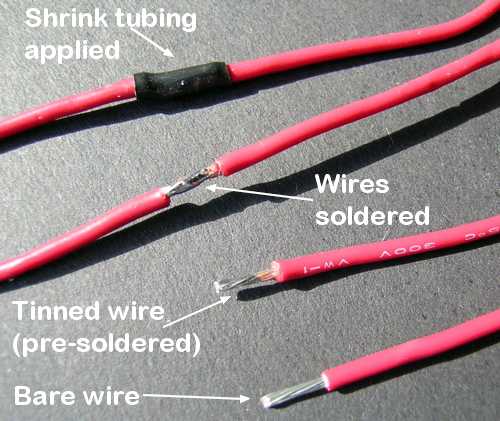

Joint the two disconnected wirings of the PCB board and connect them with a twist. Protect solder joint with heat-shrink tube as explained earlier in this guide. Repeat this process on the other wire.

/close-up-man-hands-soldering-audio-cable-with-xlr-connector-1078041206-472dd1f03b084f2b9ab373c9dff8080e.jpg)