How To Properly Solder Wires To A Circuit Board

Soldering components onto a circuit board when the leads can be pushed through holes in the board is the easier of the two methods of soldering small components onto boards.

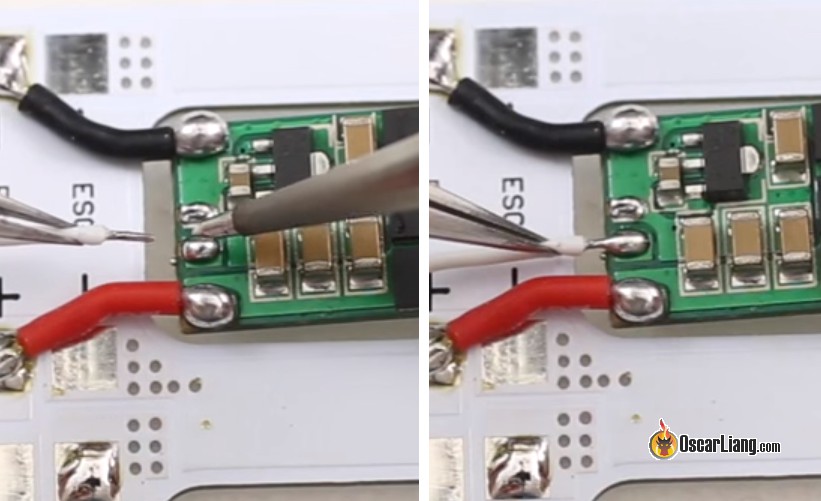

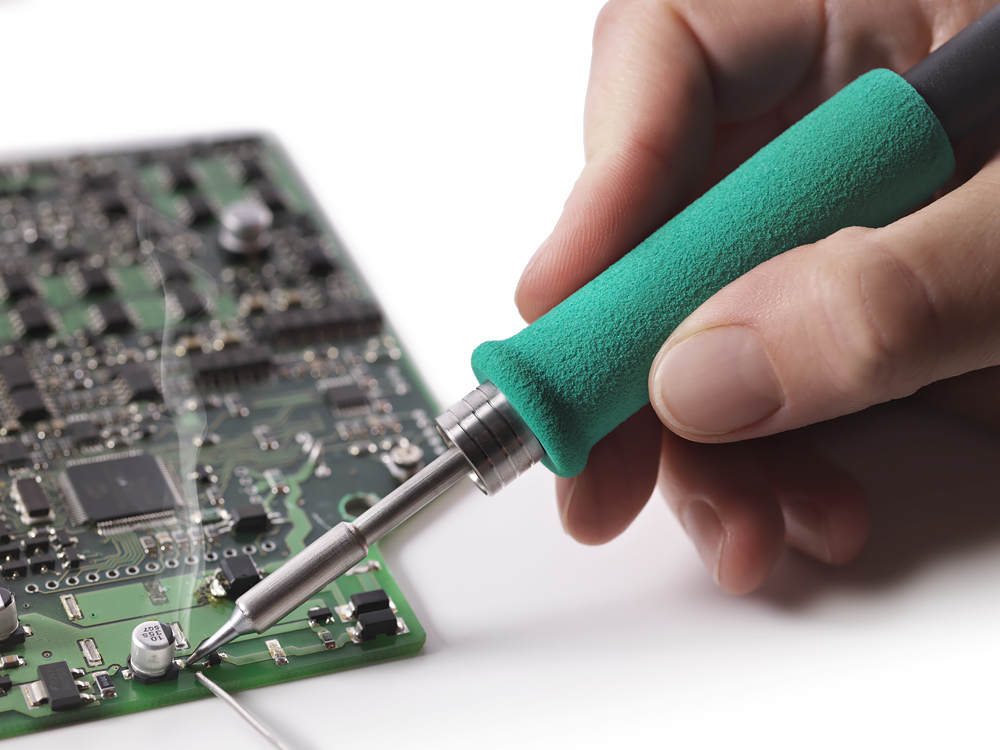

How to properly solder wires to a circuit board. Remove the insulation from both ends of your wires that youre soldering together. Keep the iron in place and touch the solder to the wire until its fully coated. Slide the iron to the end of the connection and then to the other end.

Move the iron to the opposite bottom side of the connection and repeat the same technique. A good solder joint has kind of a cone. Then touch the soldering iron to the pad and wire from the opposite side.

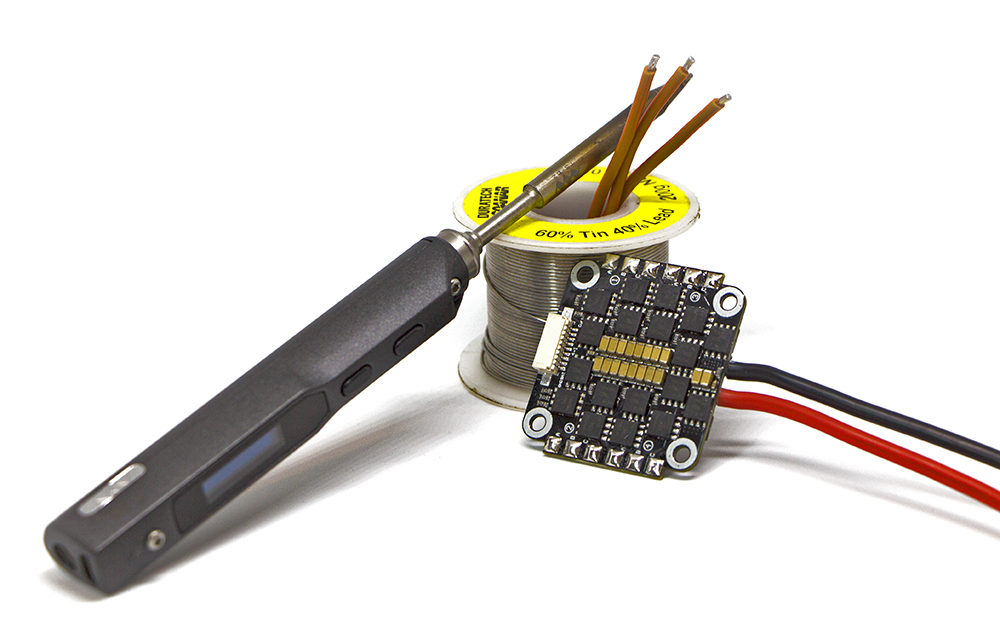

Soldering to component sockets or element pins. Soldering correctly is done by applying the soldering tip to the joint heating it and applying the solder to the hot joint to melt it into a flow. The basic fundamental of electronics soldering is to properly apply solder to create a conductive connection.

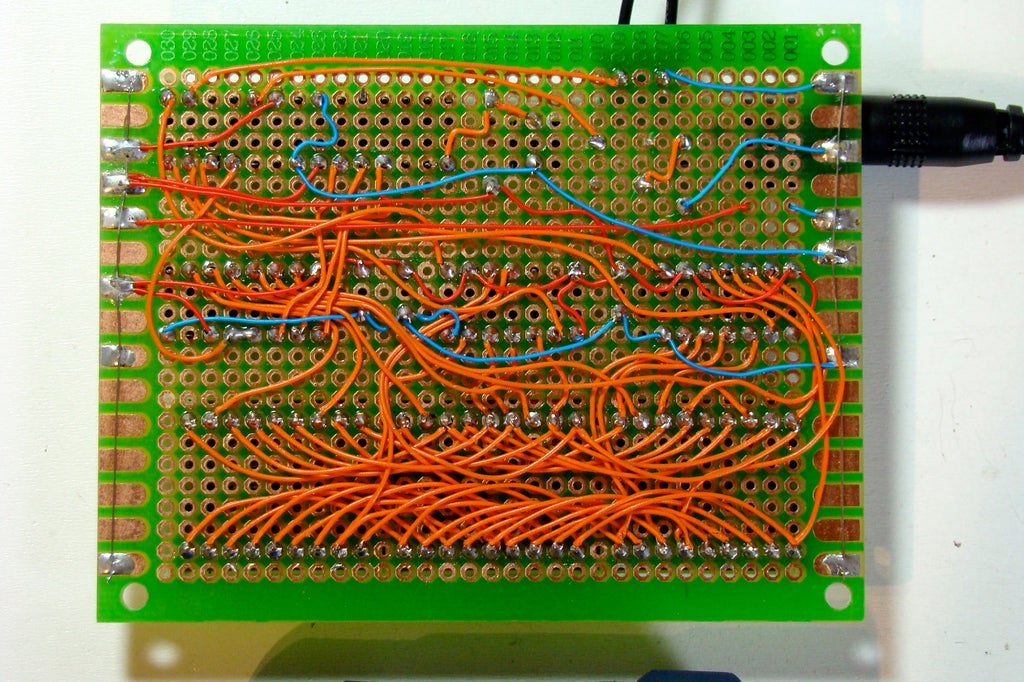

Printed circuit board Circuit Board. You should cover all of the wires with solder. Many circuit components need to be surface mounted on circuit boards which forces you to be a little more precise then when you can work on the bottom side of the board.

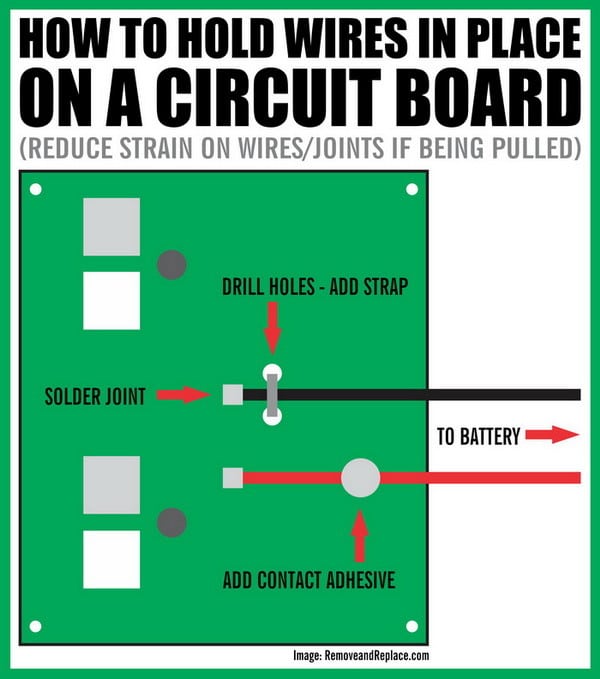

Heat them for a second or so before you apply solder. This will prevent the wires from being pulled out. Electrical tape to connect wires on a circuit board is another inexpensive and effortless method of joining wires.

Heat up your soldering iron and once fully heated touch the tip to one end of the wire. The heated wire and copper on the board will melt the solder and it Should flow very uniformly around this solder joint quite quickly. When properly soldered the connection should be smooth and shiny.