How To Solder Automotive Wiring

Continue melting the solder until theres a thin layer of solder covering all of the exposed wire.

How to solder automotive wiring. The best tool for the job is a soldering iron such as Master Appliances EconoIron. A 4060 soldering iron. During another project you pinched the wire in the door and now you have to replace it.

Remove the soldering iron and wait a few seconds to let the soldered. Tin the tip of the iron and then clean it with a sponge before heating the wire. You also have to route and support your wires in such a way that they dont flop around.

Apply enough solder so that every strand of wire is surrounded by solder. Try sourcing some alli solder it may work for your particular wire. I have tried to get the solder to attach to the wire with and without flux but no luck.

Outer diameter of single core wire. Automotive-grade stranded wire thats the same gage as the old wire. Bend the ends of both tinned wires into a U-shape with needle nose pliers.

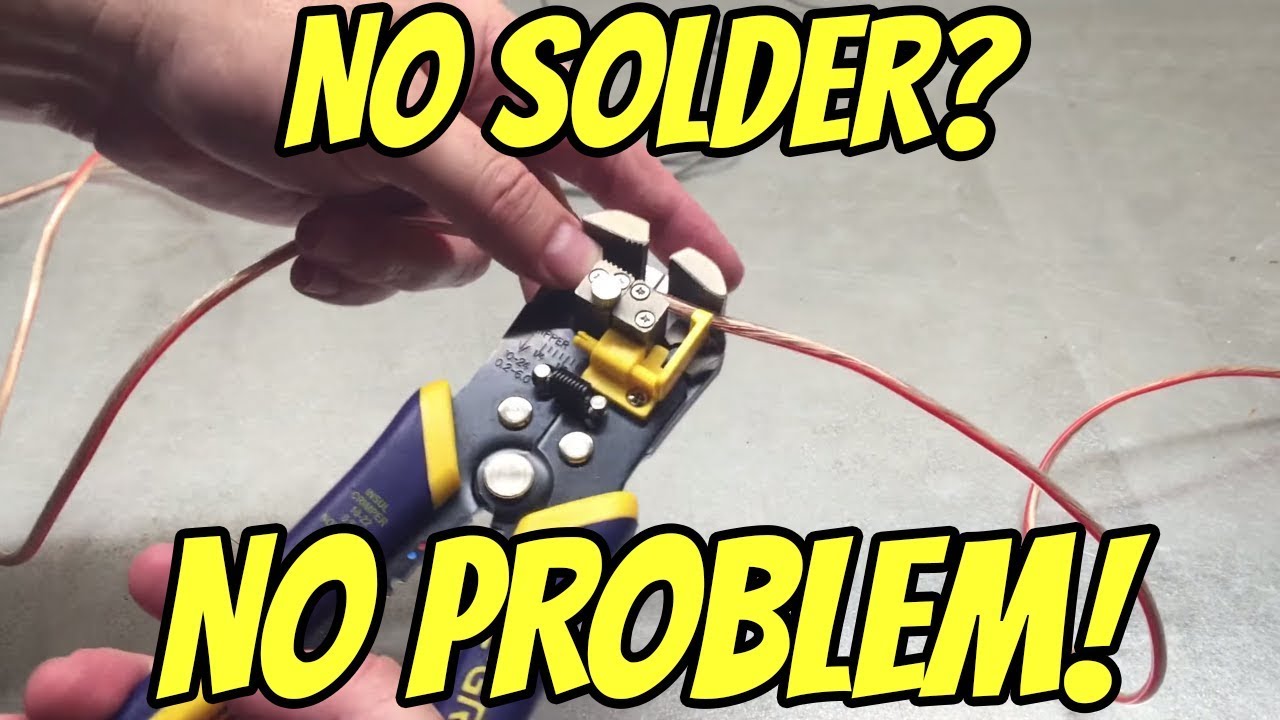

Standard automotive primary wire is 18 gauge. The other safe connection option is the crimp connector being simple and easy to use they are popular however dont always offer the longevity of soldering. How to connect two wires together is such a controversial topic among auto mechanics.

This solder melts at about 370 F. Hook them together end to. This typically allows for a 10-15 variance in draw so the window motor only draws roughly 20 amps.