How To Solder Car Electrical Wires

Run the tip of the solder on top of the wire so it melts into the wires.

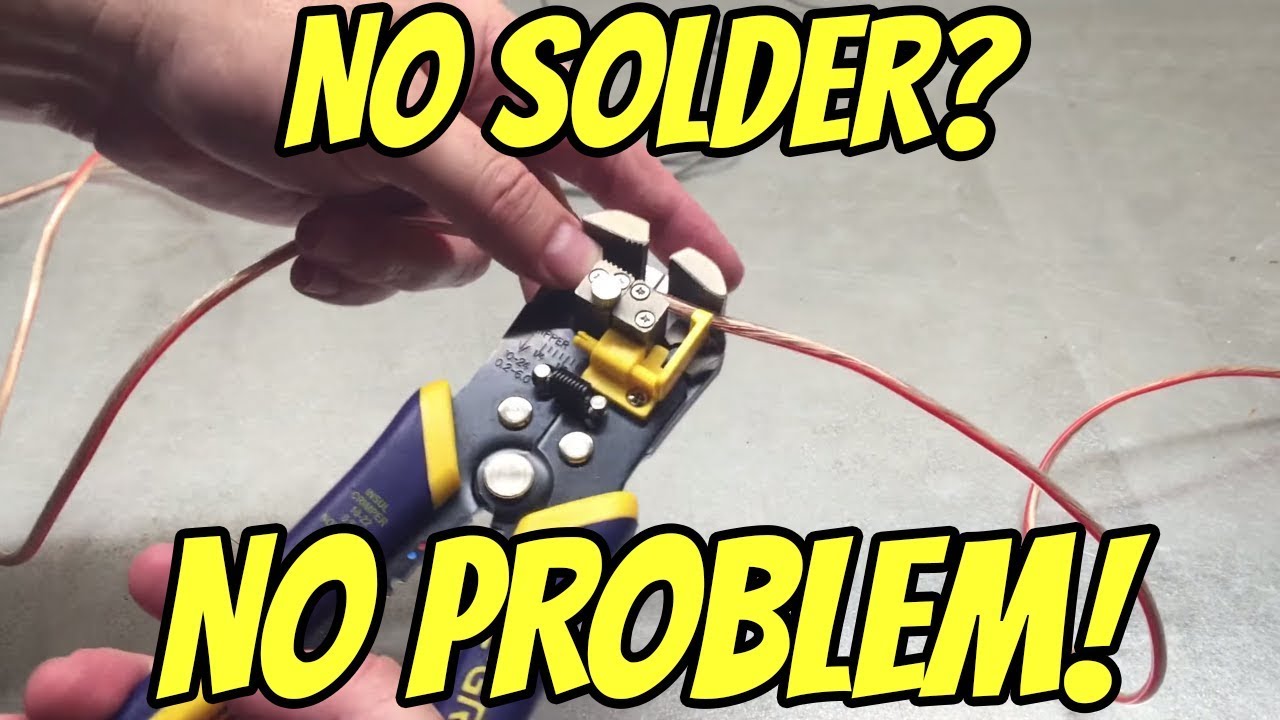

How to solder car electrical wires. However when using high-quality materials its not necessary. Make sure that you make the twisting really tight. Then just plug those numbers into this chart to determine the proper gauge.

Twist the two sections of bare wire around each other. Outer diameter of single core wire. After you are done twisting the two naked wires portion together to the top bend the twisted portion into half.

Diameter of copper core. I will show you how to solder wires together the right way to seal the solder joint with heat shrink is a must and you also need to make sure you do not have a cold solder. These are the wires Im using.

When doing splices clean the wires by scrapingbrushingsanding solder tin the wires to be joined slide clear heat shrink tubing over one wire lay the tinned ends together and touch them with the soldering iron and they will fuse nicely then slide the clear heat shrink tubing over the joint heat shrink one end pack it with petroleum jelly then heat shrink the other end. How to Solder Car Wiring. The best solution to cover soldered wires is heat shrink tubing and it must be installed BEFORE the soldering is done.

You may need to re-tin at some point during the process. Soldering a Wire to a Pre-Existing Wire in the Vehicle. Apply a little solder to the tip before applying heat to the twisted wires.

Now i heat it up toward the bottom of the lug until i see the wire underneath pull the solder into it. In the case of twisting start twisting them really tight together all the way to the top. Wrap one or two inches of solder around the tip while the iron is cold.