How To Solder Fine Electrical Wires

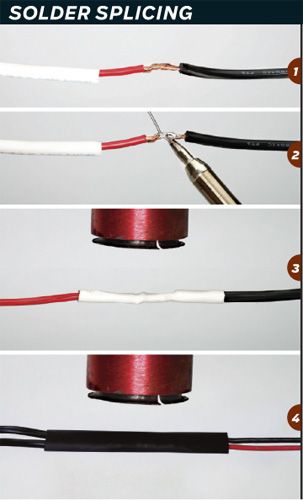

Hold the two tinned wires on top of each other and touch the soldering iron to both wires.

How to solder fine electrical wires. How to Solder Two Small Wires - YouTube. If you use flux it must be for electronics any other will ruin the wire in a short time as most are acid. A clean surface is required for good soldering.

The solder should be fed into the cool side away from the heat which allows it to be drawn in smoothly by the heat transfer through the wires. Tinning is a process of using a soldering iron to melt solder around a stranded electrical wire. If you did the cable and the tag at the same time by the time the solder properly melted the wire insulation would have started to melt.

If that is enammelled wire as it appears then as others have said the best method of stripping is to heat the ends with a flame to destroy the insulation and scrape off the residue. Repeat this process on. Making a soldering litz wire is of as following.

When you are tinning the wires the resin will help the solder flow smoothly. Remove the soldering iron and allow the soldered connection to cool and harden for a few seconds. The solder should flow freely into the wire and coat it.

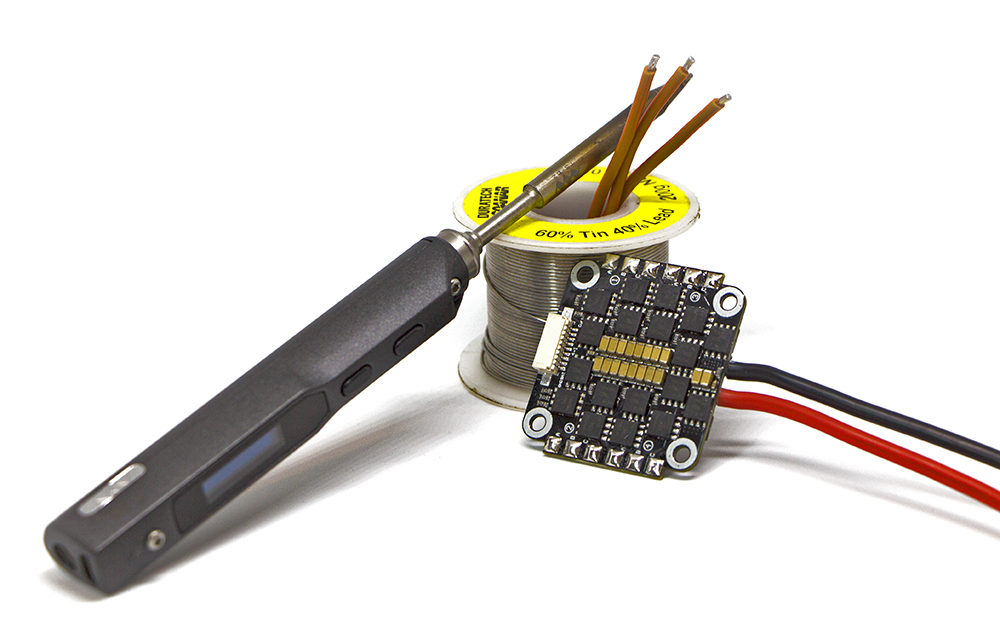

Heat the end of the wire to burn the insulating material and sand carefully with fine 400 grit sandpaper by folding it with the grit inside and running the wire end through it. The solder jar is made up by approx. 60tinpine resin and 40lead.

The advantage of solder is that. Make sure your soldering iron is fully heated and touch the tip to the end of one of the wires. Begin by removing the insulation from the ends of both wires you are soldering together.