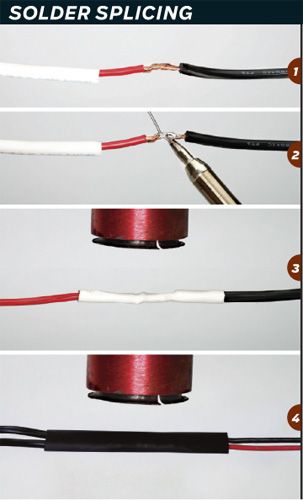

How To Solder Small Electrical Wires

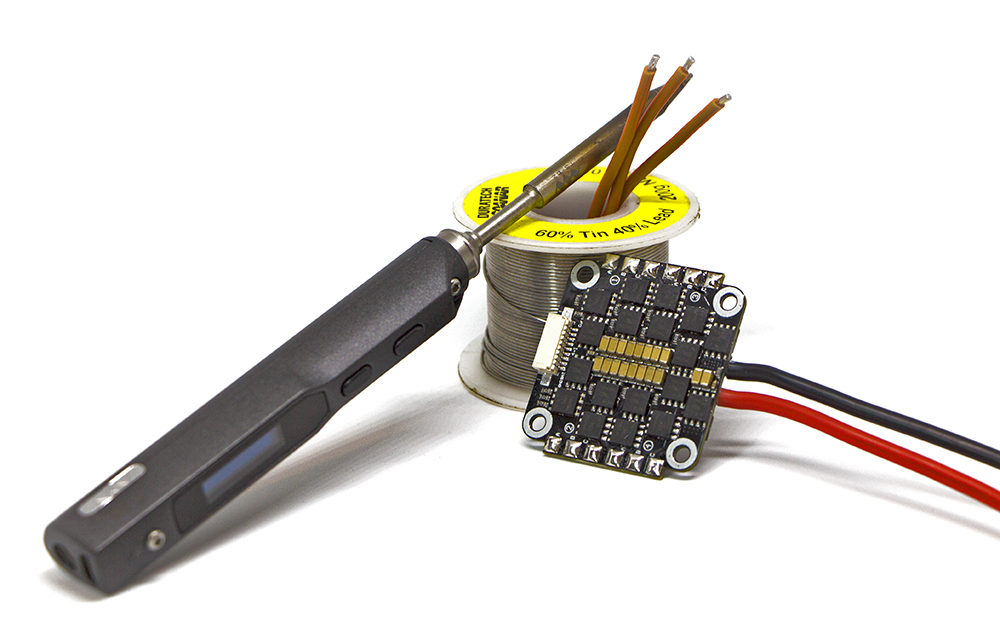

Use a pencil soldering iron like the one in the same picture.

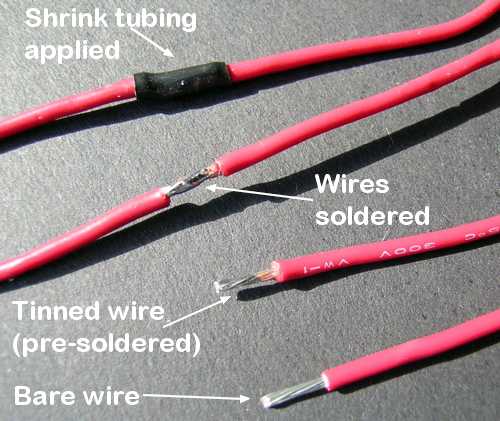

How to solder small electrical wires. Ad Low-Price High-Quality electronic Connectors Ready to Ship. If you tin the wires and the holes you will need very little or none additional solder. After you put the wire in a hole heat the junction of the wire and hole until the solder on the wire and hole melt should take no more than 2 seconds.

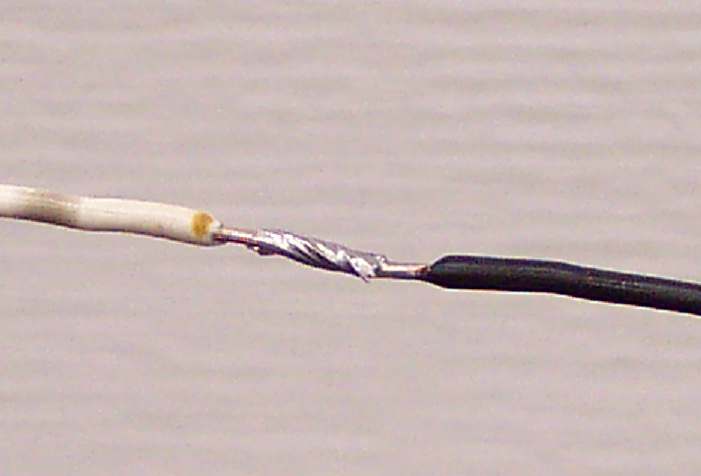

Meets The EU RoHS Directive 201165EU Claim. Offer a Variety Of Connectors. I solder the shield connection first.

Always tin each wire tip individually so the connection process is only a quick touch of heat. Request a Quote Today. The solder should be fed into the cool side away from the heat which allows it to be drawn in smoothly by the heat transfer through the wires.

Glue or tape it to the board with tape under if needed for insulation so. Sold in the electronics department. Meets The EU RoHS Directive 201165EU Claim.

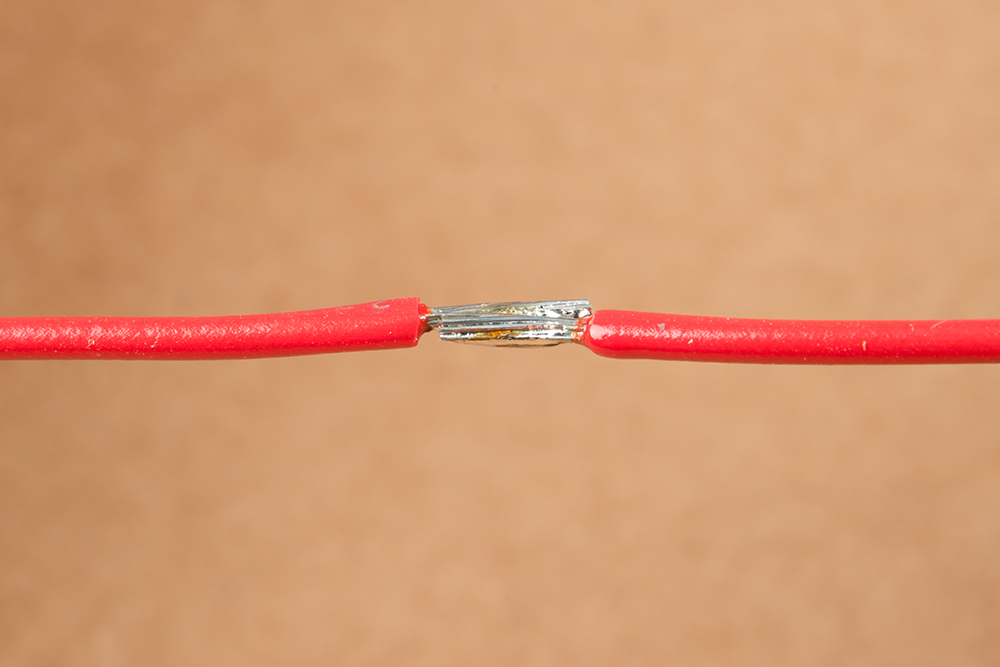

Hold the two tinned wires on top of each other and touch the soldering iron to both wires. Solid core solder. This will help conduct heat to the wire.

Automotive wiring should be soldered and protected properly in order to withstand all types of weather rain snow and salt. Ad Quality Solder Wire Drawing Machine. With a drop of solder on the iron you hold the wire in the drop and add a bit of resin core electronics solder and the wire will take the solder if a few moments.

/close-up-man-hands-soldering-audio-cable-with-xlr-connector-1078041206-472dd1f03b084f2b9ab373c9dff8080e.jpg)