How To Tell If Soldering Tip Is Bad

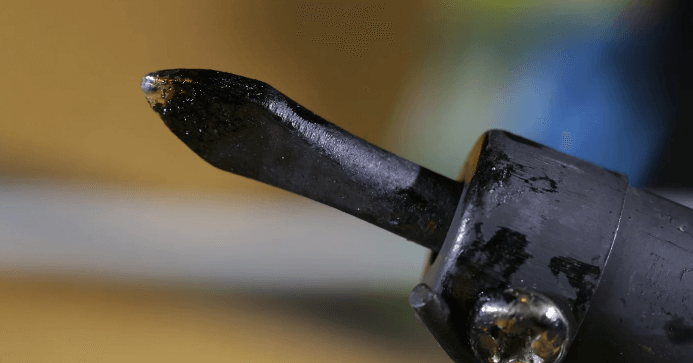

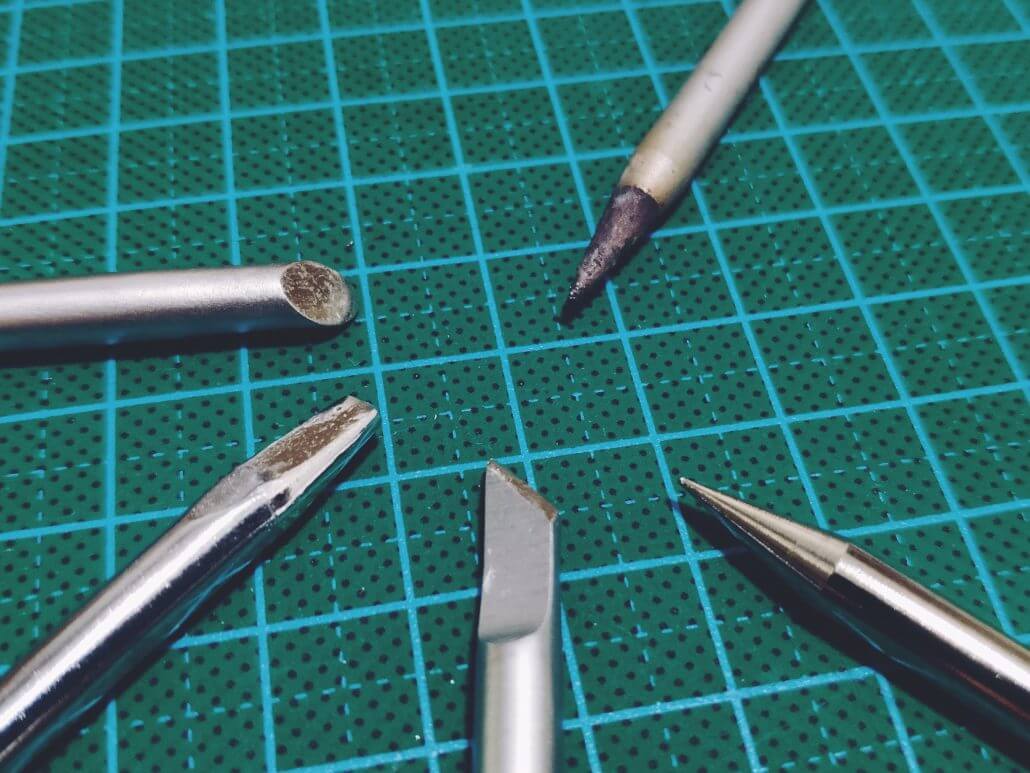

When the tip isnt properly maintained which is to say kept clean and regularly tinned oxides will begin to accumulate on the shanks surface.

How to tell if soldering tip is bad. This help keeps the tip from oxidizing. Always return the soldering iron to its stand when not in use. IMPORTANT Dont touch the solder directly to the tip of the iron.

Keep the cleaning sponge wet during use. Dont blow on the solder as this will cause a bad joint. If however the soldering iron is still generating some heat the issue is probably the soldering iron tip.

Snip The Leads Remove the soldering iron and let the solder cool down naturally. Too much solder too little solder cold joints dry joints failing to wet the joint properly a plethora of terms are explained if you read one of the many online guides to soldering. If the solder doesnt melt turn the dial up by only one division and wait a minute.

Keep that in mind. Especially lead-less solder is more critical than solder that contains lead. Also use an ohmmeter and go from the components leads component side so for like a resistor cap transistor you actually try to.

Keep turning up the dial until you. Bad solder joints often look dull not shiny chrome-like like a good solder joint. Snip The Leads Remove the soldering iron and let the solder cool naturally.

If the joint is too cold a bad connection is formed. It may help to grip the solder wire around 5 inches 13 cm from the tip of the wire that is being soldered so as to distance your hands from the hot solder. Just do the RAM troubleshooting as mentioned above if you suspect the RAM is faulty.