Soldering Iron Tips Wear Out

There are various factors that make every soldering iron tip wear out.

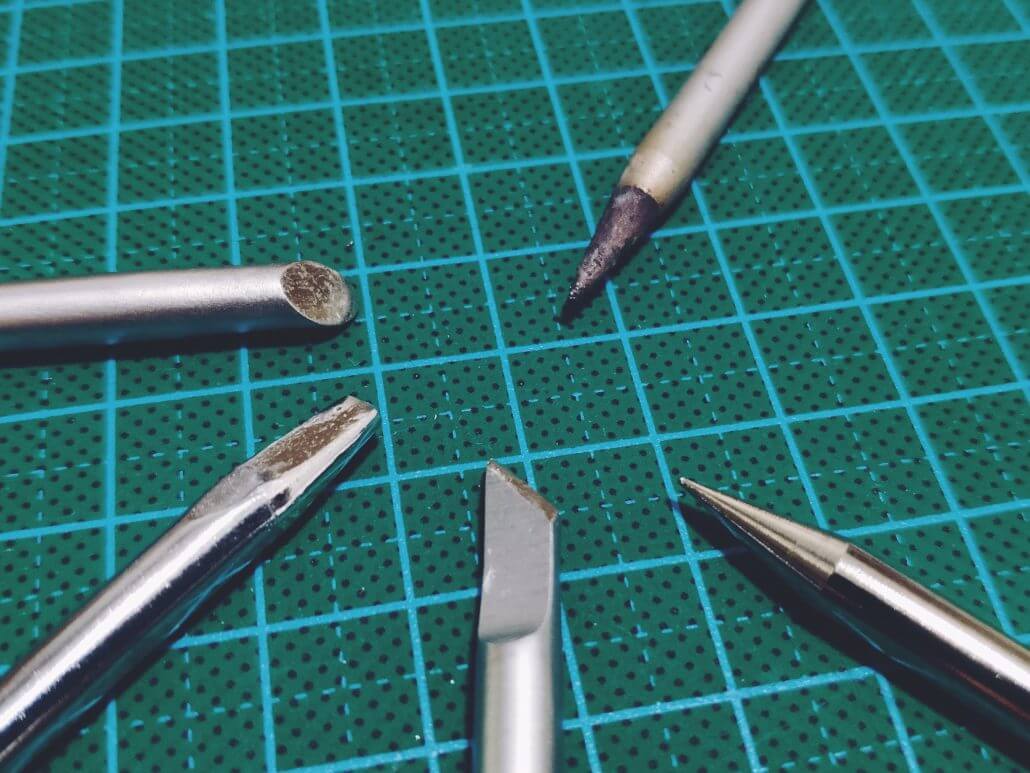

Soldering iron tips wear out. The oxidation process occurs when metal is left in an oxygen-rich atmosphere. It is not impossible to do point soldering with this tip but it is considerably difficult as compared to the other tips. Soldering tips may wear out prematurely especially if you dont know how to use it properly.

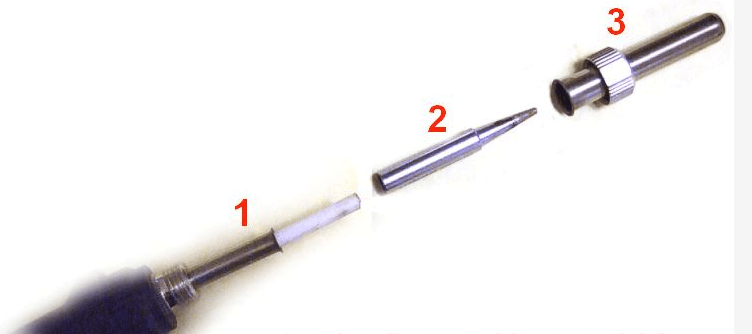

Theres also a great deal of variety out there when it comes to soldering iron tips. Tips can wear out too - I had an old Radio Shack soldering iron and used it for years and even took a file to the tip to abrade off the bad and carbonized surface but it was very old and worn out. The plating layer wears out exposing the copper core leading to corrosion.

Common signs that the tip needs replacing are. All tips eventually wear out due to heat and normal use. NEVER file a soldering tip.

If you clean off the rust and spot a hole in the iron coating recognizable by the copper color showing through from the inside or if any part of the tip appears hollowed out its done. Touch the solder to the tip of the iron and make sure the solder flows evenly around the tip. Ive got both JBC and metcal and use the Metcal mostly because tips are a lot cheaper so i can afford to have a lot of different tips.

Oxidation is one of the major culprits of wear out in soldering iron tip. First theres the one commonly known as a b-series tip. If you need to desolder something or have a glob of solder using a desoldering suction tool couple bucks from eBay or AliExpress to suck up the liquid solder instead of using your iron to pick it.

Common signs that the tip needs replacing are. Soldering Iron tips do not last forever. Corrosion from acidic or highly aggressive fluxes.