How To Improve My Stick Welding

For example with a 18 inch electrode thats 0125 inch or 125 thousandths.

How to improve my stick welding. Skill comes only with practice. Weld splatter is not a good look mostly you will get weld splatter during arc or stick welding and even with the best MIG welders. Use a wire brush or grinder to remove dirt grime or rust from the area to be welded.

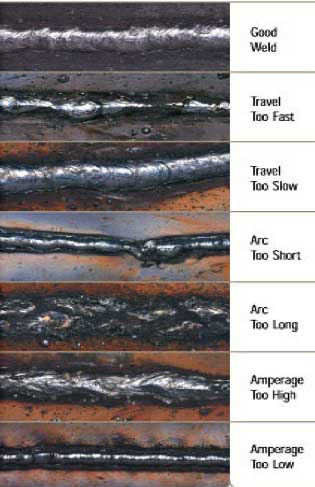

8 Beginner Tips to Make Better Stick Welds in 5 minutes - YouTube. I hope someone can use this tidbit. When stick welding for the first time most people find it logical to have a long arc usually to have a better view of the weld puddle.

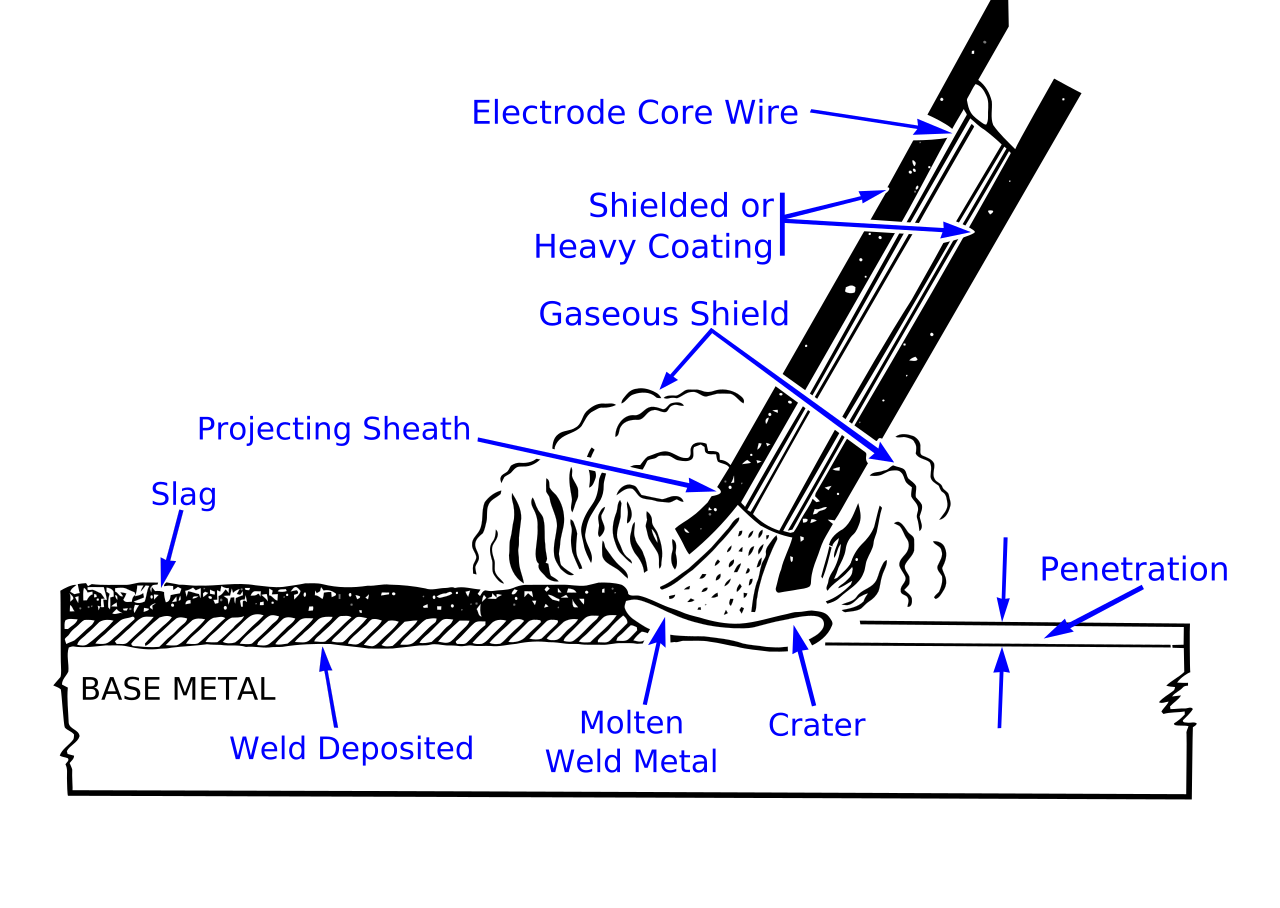

To increase bead size use slower travel speed and a short arc technique or weld 5 degrees uphill. The following pages will help the inexperienced welder to understand welding and develop his skill. When you pull you can see the puddle but its hard to see where you are going because the nozzle blocks your view.

While stick welding may be the most forgiving process on dirty or rusty metal dont use that as an excuse for not properly cleaning the material. Remove the welding stinger from the electrode as fast as you can turn off the welder and break off the rod from the metal. When you push you can see where you are going better but the puddle is blocked by the nozzle.

Always continue welding while the plate is hot Rigid parts are more prone to cracking. Simply think about CLAMS. The DCEP polarity increases the weld bead width by increased globular metal transfer.

Vertical up or 3G point the rod up between 30 to 45 degrees. HAZ or Heat Affected Zone. Horizontal or 2G you point the rod upward between 30 and 45 degrees and drag it toward your direction of travel with a side tilt of 10 to 30 degrees.