How To Improve Soldering Process

Once the solder begins to flow to the back side along with the direction of the board bridges will begin to appear.

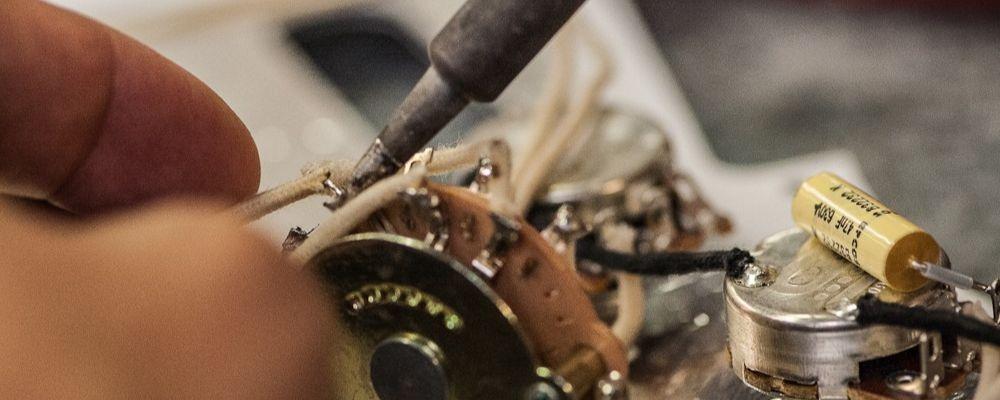

How to improve soldering process. To prevent burning your ngers use needle nose pliers heat resistant gloves or a third hand tool to hold small pieces. This includes solder ux alcohol and desol-dering braid. Increasing time above liquidus will help to allow for the complete flow of the liquid solder before it begins to freeze.

Be careful that give too much of the solder paste volume under the BGA will bring solder short. 3D Printing Helps Researchers Improve Electrochemical. After cleaning wipe the tip with moist cotton or sponge.

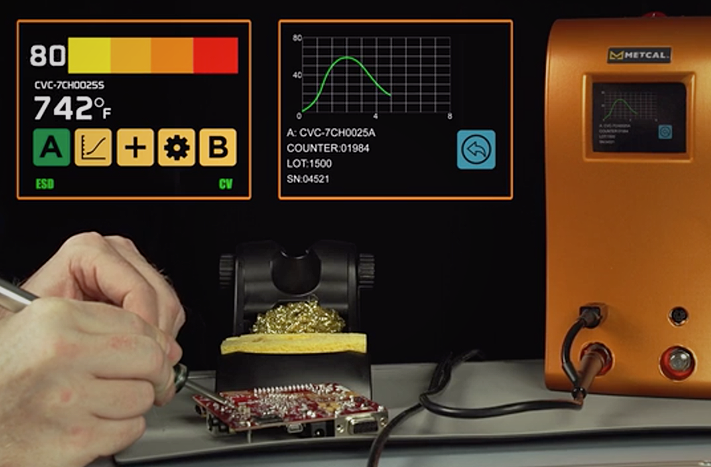

If the soldering iron tip isnt responding to the extra solder revive dirty. In the soldering of bare copper OSP with lead-free alloys such as SnAgCu or SnCu the following can be tried to improve hole-fill. To change the amount of solder paste of the BGA you can start from Stencil.

Begin by making sure the tip is attached to the iron and screwed tightly in place. Preheating of PCBs is done using hot air heaters. The solder should flow in the opposite direction from that of the assembly.

Once the solder flows remove the heat source immediately. Tinning will also help to protect the tip and reduce wear. Involves preheating fluxing soldering using a wave of solder cleaning and quality.

Here WorkingBear modify the stencil aperture size for BGA package to control the solder paste volume. The soldering process can be applied in electrical and electronic projects plumbing etc. Since the soldering process is intermittent keep the soldering iron tip on a heat sink.